Burners

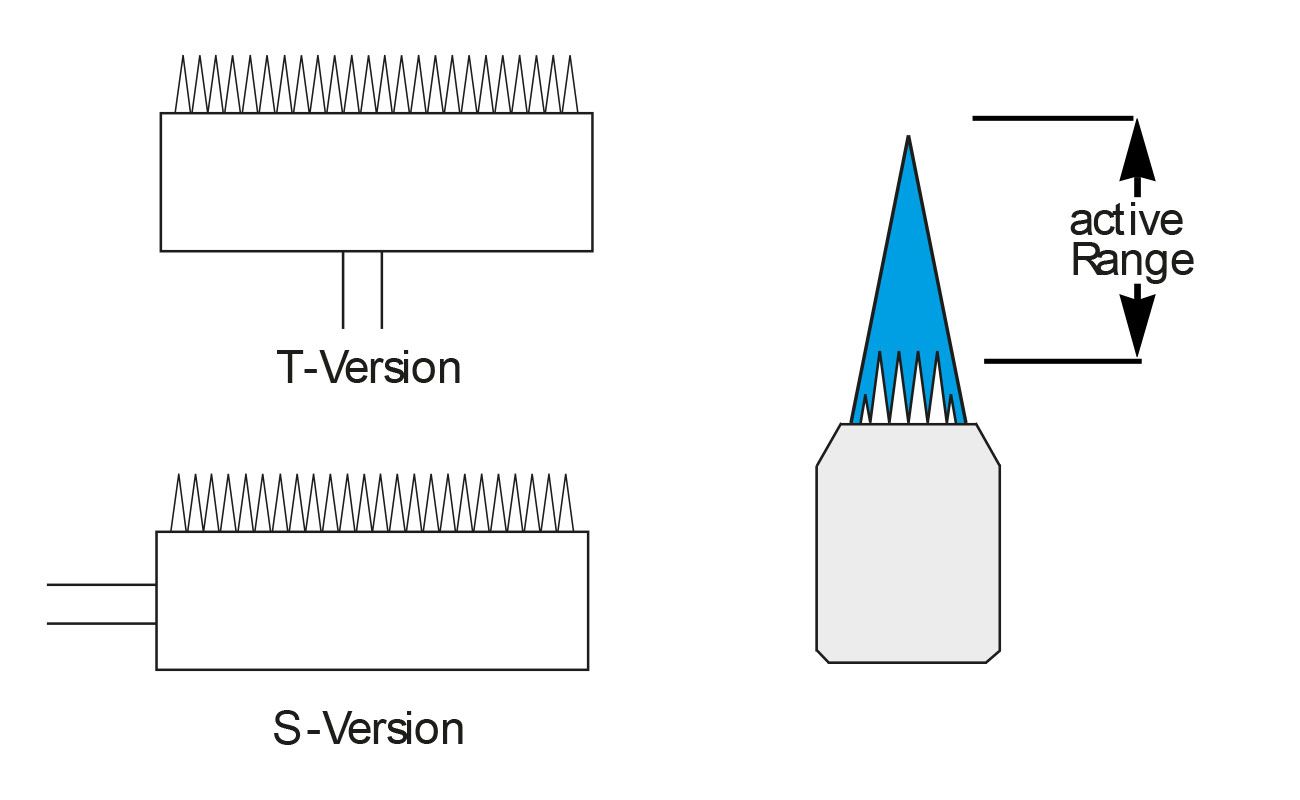

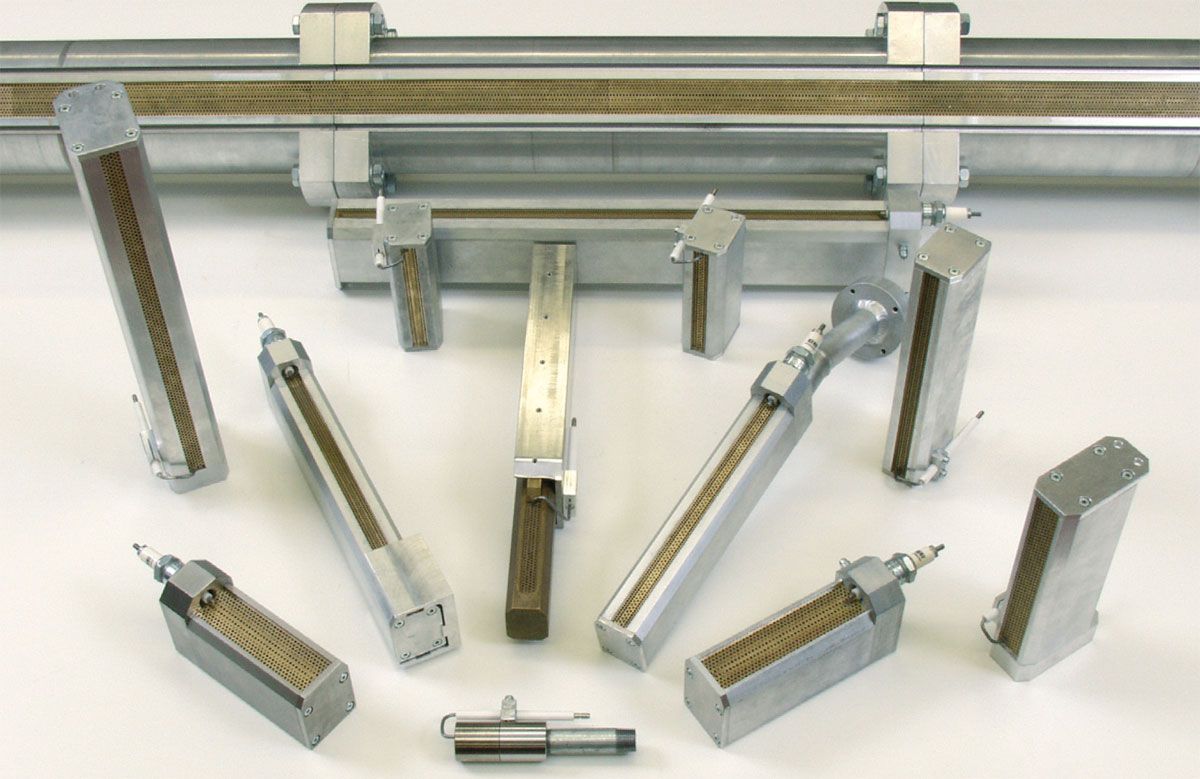

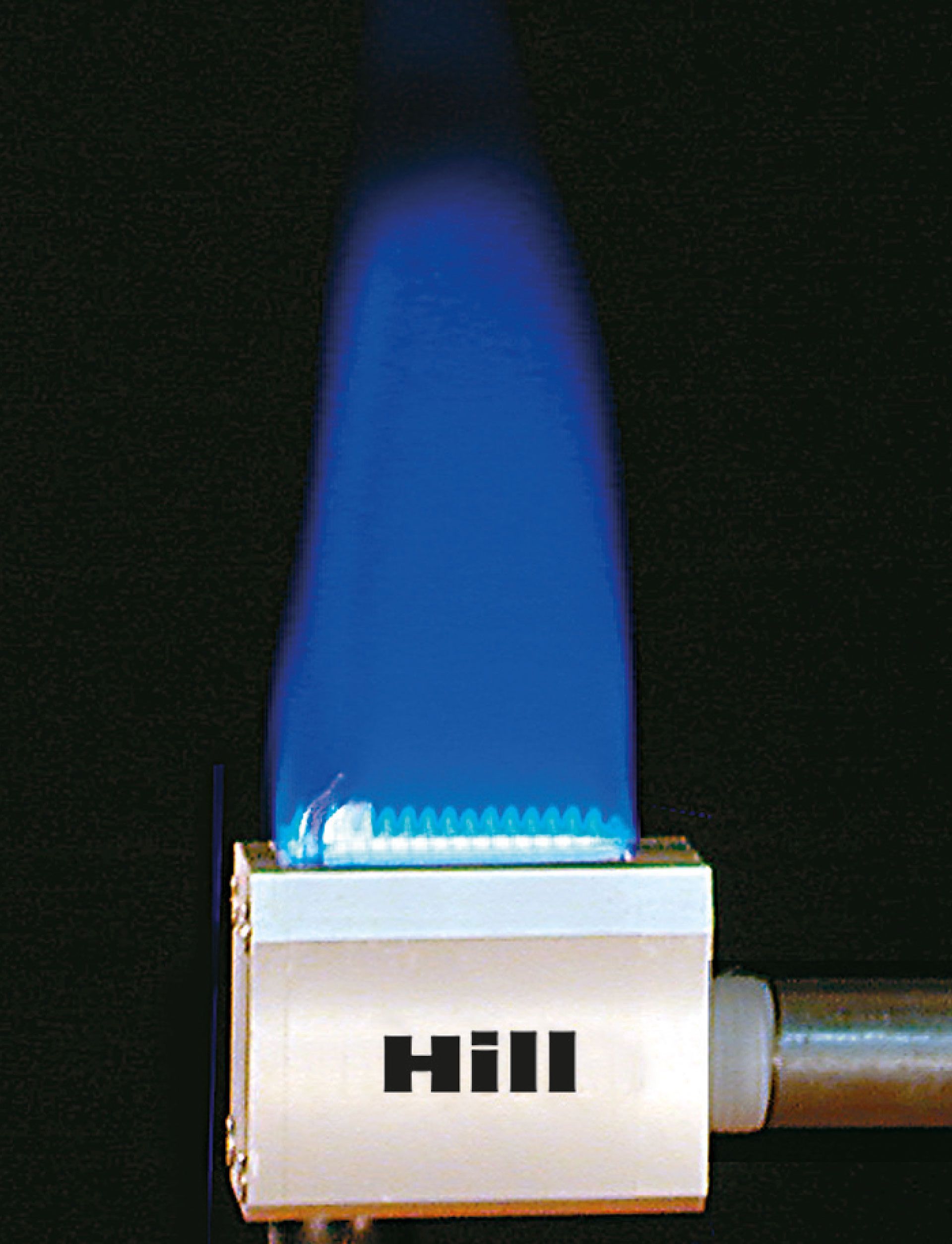

Selecting the appropriate burner is a key factor for pretreatment. Burners differ in their heat output and the geometry of the flames they produce. The active flame area must be selected to optimally cover the geometry of the substrate to be treated. A basic distinction is made between single-row and multi-row burners: Single-row burners produce a "soft" flame, which is used for flat to slightly textured surfaces. Multi-row burners operate at an increased flow velocity to create a particularly long, active area. To prevent the flame from lifting off, pilot flames are formed on both sides, which continuously re-ignite the main flame.

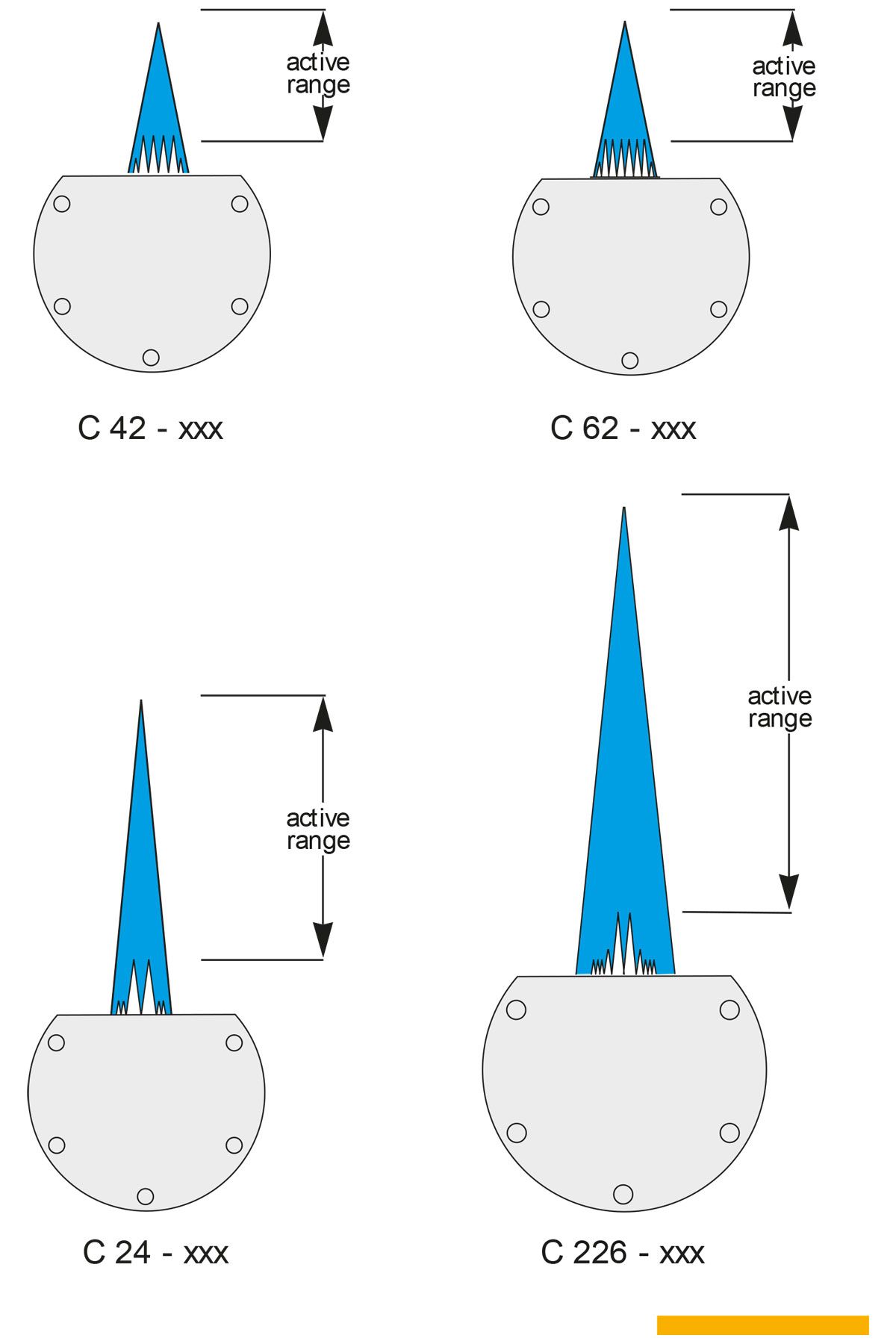

Series 42

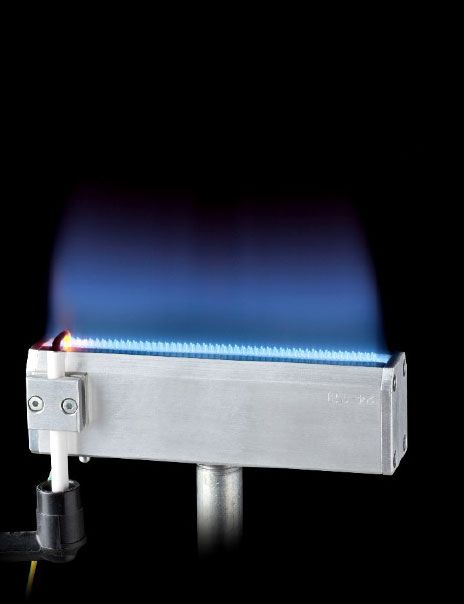

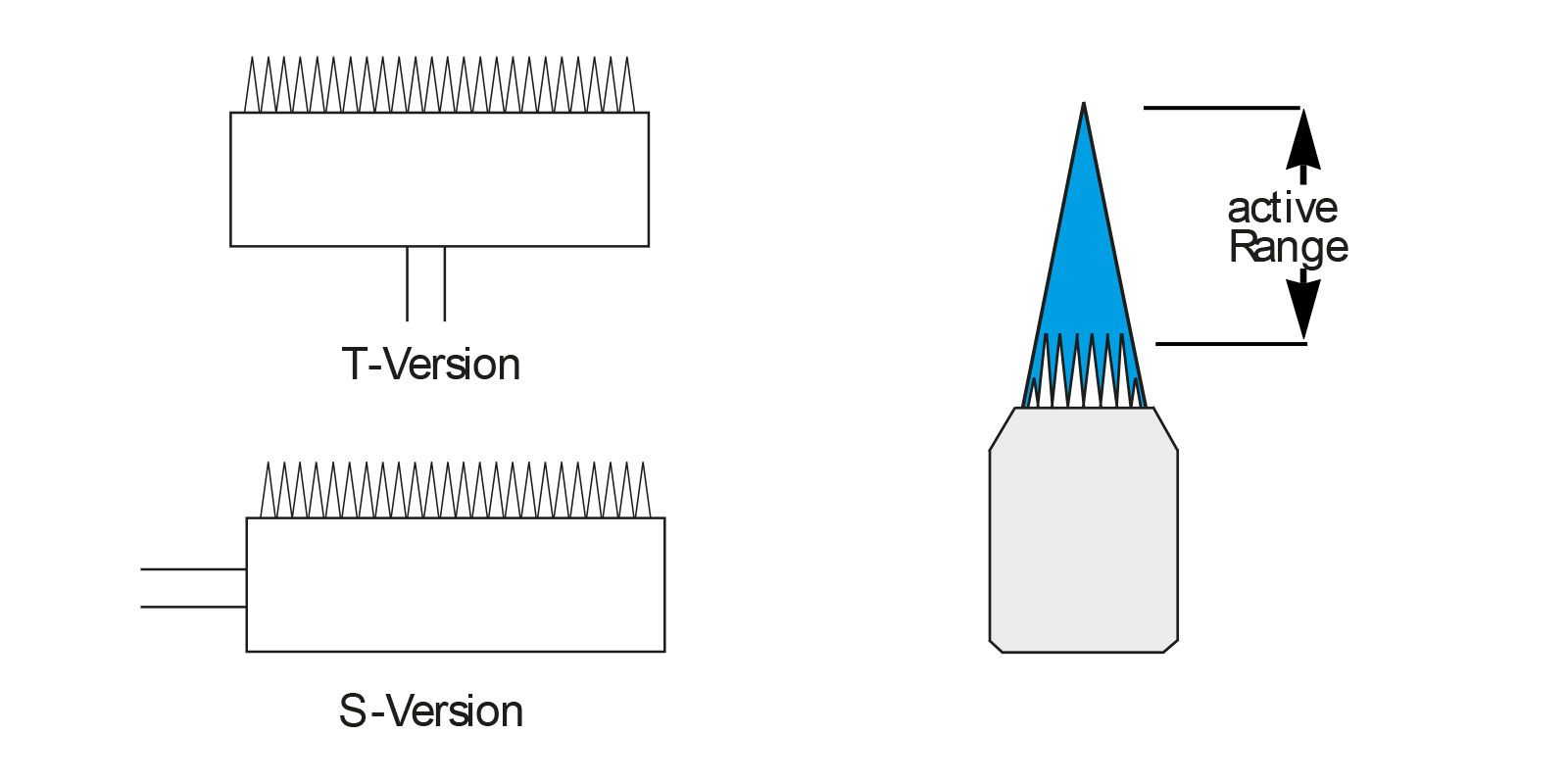

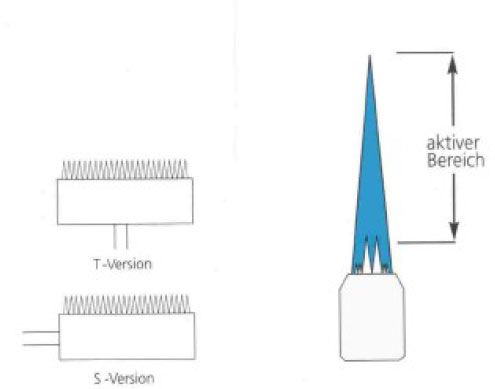

Burner Series 42

- Single-row standard burner

For pretreatment of flat surfaces and slightly structured molded

parts

- Active range 20 - 80 mm

Versions:

- S version: side connection

- T version: central connection

- Working widths: 50 - 450 mm

Order example:

S 42 - 150

S – side connection42 – single row burner150 - 150 mm working width

Maximum power output:

0.65 kW / 10 mm working width

Series 62

Burner Series 62

- Single-row high-performance burner

For pretreatment of flat surfaces and slightly structured molded parts

- At high speed or generally increased power requirements

- Active range 20 - 80 mm

Versions:

- S version: side connection

- T version: central connection

- Working widths: 50 - 450 mm

Order example:

S 62 - 150

S - side connection

62 - single-row burner

150 - 150 mm working width

Maximum power output:

1.3 kw / 10 mm working width

Series 24

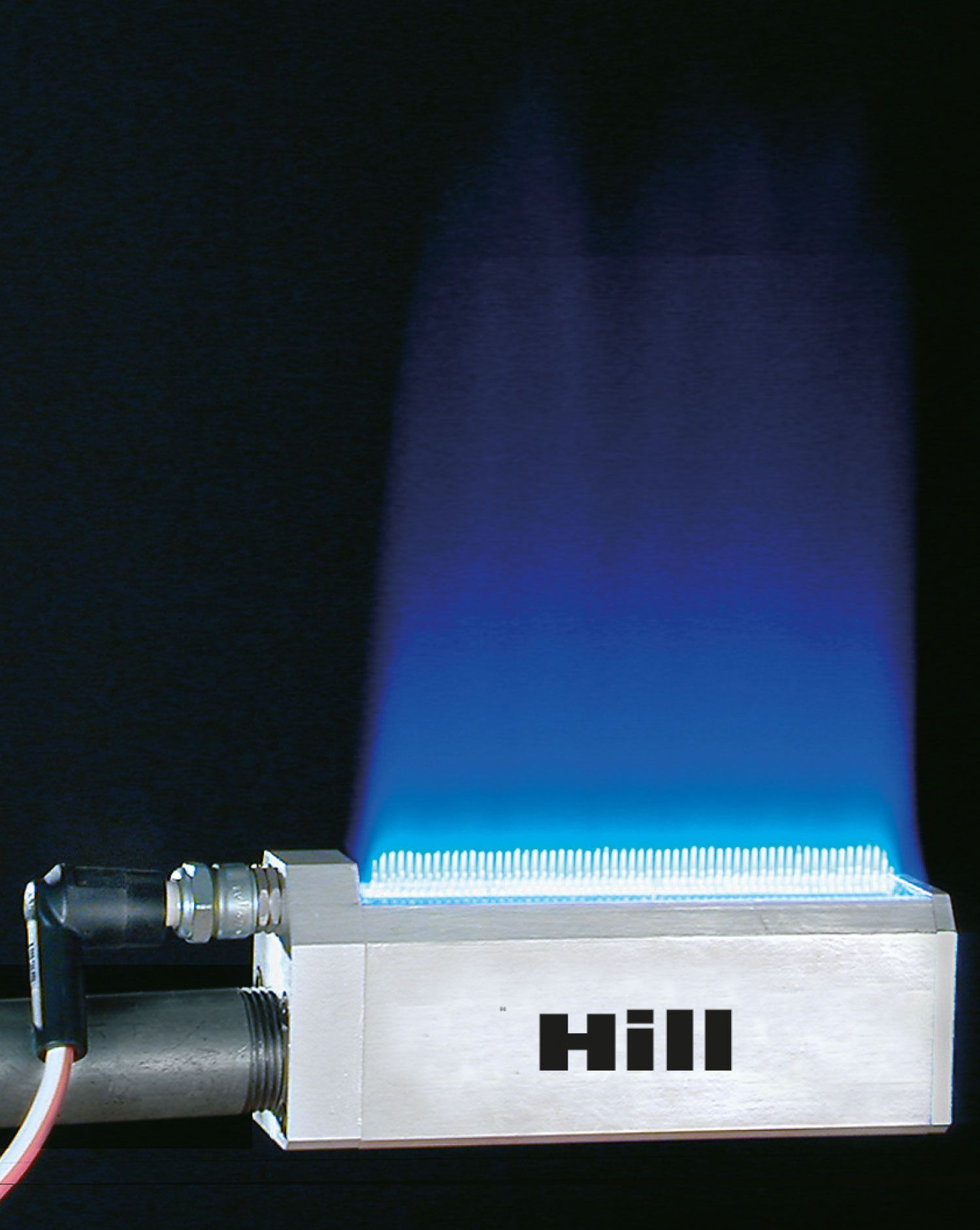

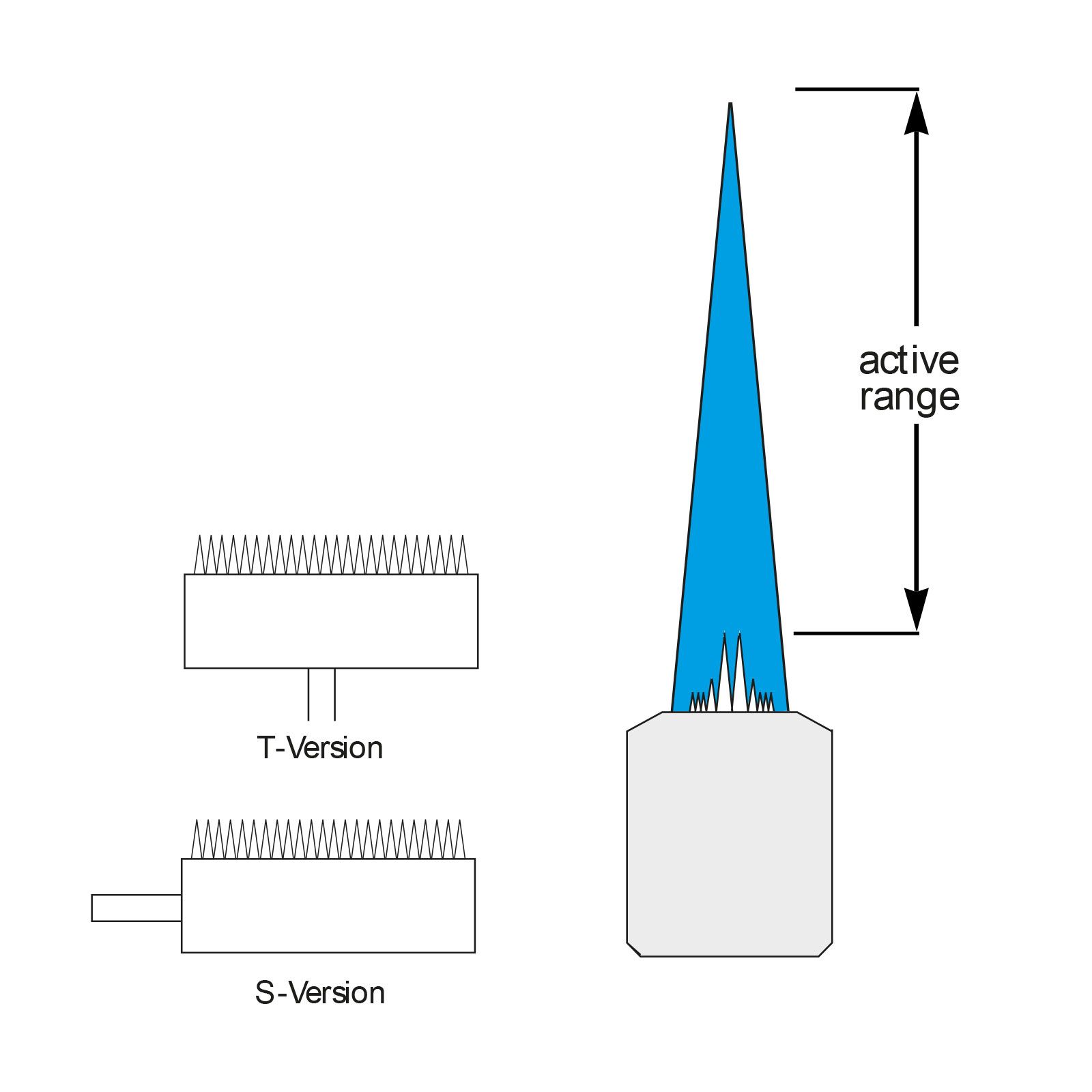

Burner Series 24

- Three-row universal burner

- For pretreatment of surfaces at high speeds and for medium to heavily structured molded parts

- Active range 20 - 150 mm

Versions:

- S version: side connection

- T version: central connection

- Working widths: 50 - 450 mm

Order example:

S 24 - 150

S - side connection24 - single row burner150 - 150 mm working width

Maximum power output:

1.3 kw / 10 mm working width

Series 226

Burner Series 226

- Three-row high-performance burner

- For pretreatment of highly structured molded parts

- Active range 40 - 250 mm

Versions:

- S version: side connection

- T version: central connection

- Working widths: 50 - 450 mm

Order example:

S 226 - 150

S - side connection226 - three-row burner150 - 150 mm working width

Maximum power output:

2 kw / 10 mm working width

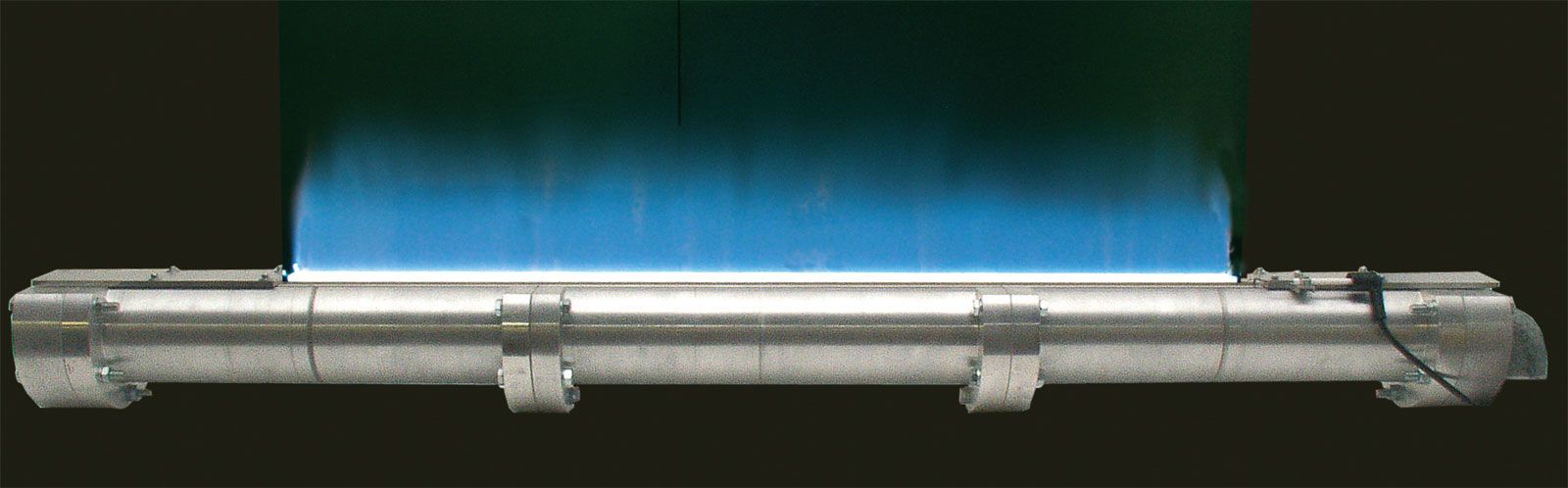

C-Series

Burner C-Series

- Water-cooled burner in segment design for film applications

- Working widths from 500 - 10 000 mm

- Optionally adjustable working width

Versions:

- C 42 - xxx 0.65 kw / 10 mm working width

- C 62 - xxx 1.3 kw / 10 mm working width

- C 24 - xxx 1.3 kw / 10 mm working width

- C 226 - xxx 2 kw / 10 mm working width

- C 58-xxx 2,6 kW / 10mm working width

Order example:

C 42 - 1500

C - side connection42 - single row burner1500 - 1500 mm working width

Round burner RB28

- Single-flame round nozzle for pre-treatment of limited area adhesive surfaces and grooves at speeds between 0.5 and 1.0 m/sec.

- Effective range depending on the set power: 30-100mm

- Can also be used to remove tinsel and burrs from injection-molded parts after demolding.

- maximum power output 5.5kW

Series 14

- Single-row pretreatment burner for flat to slightly structured component surfaces with very thin material thickness.

- Can also be used for flame polishing of decorative plastic substrates.

- Effective range depending on the set power: 5-50mm

- Working widths from 25mm to 8,000mm

- maximum power output 0.4kW/10mm working width

Series 58

- Three-row pretreatment burner for flat to highly contoured component surfaces.

- Universally applicable for the pretreatment of plastic surfaces, metal and glass surfaces as well as cardboard webs at high processing speeds

- Effective range depending on the set power: 20-150mm

- Working widths from 25mm to 4000mm

- maximum power output 2,6 kW/10mm working width

Sectioning of the effective areas possible see picture.

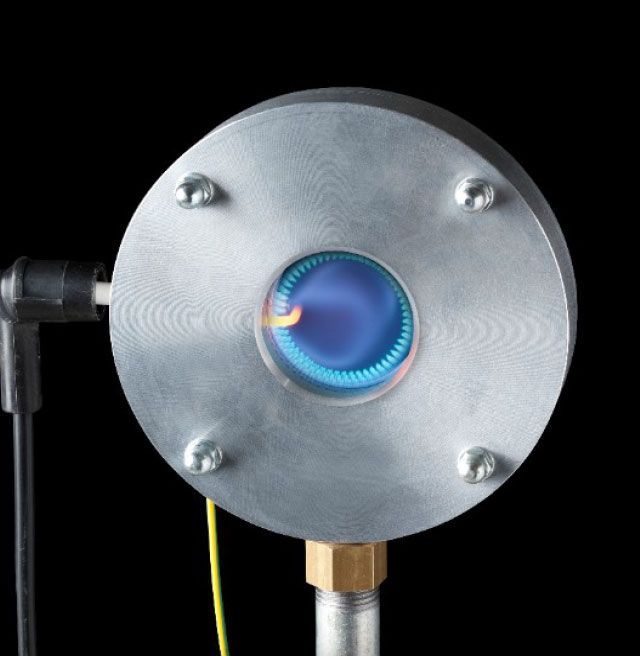

Ringburner Series R

- Single-row annular burner for pretreatment of pipes, hoses, cables and plastic profiles

- directly in the extrusion process or in the processing of fixed lengths

- with appropriate material transfer available diameters : Ring burner R15 : 30mm Ring burner R20 : 40mm Ring burner R25 : 50mm Ring burner R30 : 60mm Ring burner R40 : 80mm

Round burner R60 A

- Round burner with annular nozzle outlet in 60mm diameter

- Nozzle ring with bore pattern of series 14,24,42 possible.

- Mainly used for the pretreatment of bonding surfaces or in the area of component deburring and flame polishing