Process description

The use of a gas flame to improve adhesion on difficult-to-wetting surfaces, especially on polyolefins such as polyethylene (PE) and polypropylene (PP), was first introduced in the 1950s by Professor Werner Kreidl in the USA and has since been known as the Kreidl process.

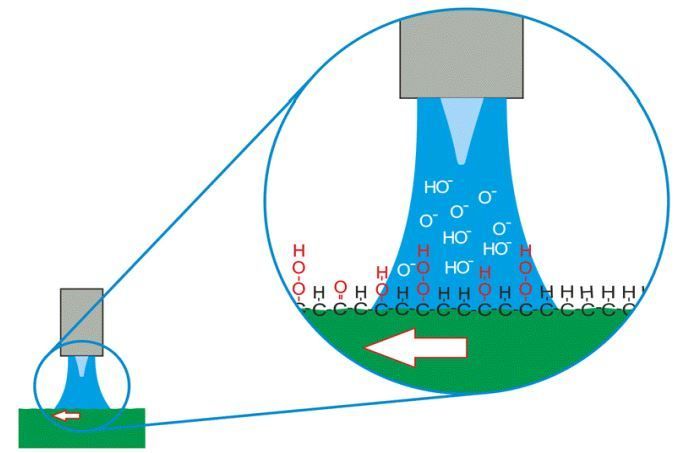

In this process, the surface to be treated is exposed to the direct action of an open gas flame for a very short period of time. This flame is operated with a defined excess of oxygen, creating an oxidizing atmosphere. The decisive factor here is not the heat input, but the targeted chemical modification of the surface by the reactive species contained in the flame.

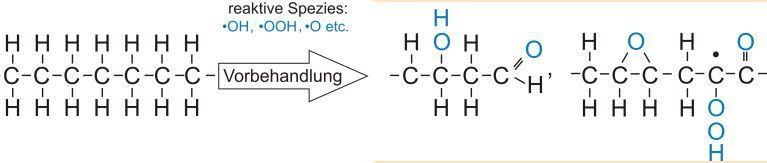

The high temperature of the flame temporarily breaks existing molecular bonds in the uppermost layer of the substrate. In the oxidizing zone of the flame, reactive radicals and functional groups, particularly hydroxyl (–OH), carboxyl (–COOH), and carbonyl (–C=O) groups, are formed, which can be incorporated into the polymer matrix. This specifically polarizes the originally nonpolar and chemically inert surface.

The introduction of these polar groups leads to an increase in the surface energy of the material, which significantly improves its wettability. This is a prerequisite for the secure and permanent adhesion of subsequent coatings, such as printing inks, varnishes, or adhesives. The effect is usually measurable immediately after treatment and remains stable for a certain period of time with appropriate storage.

A critical aspect of flame treatment is the precise adjustment of the gas-air mixture. Only with a constant and sufficiently large excess of oxygen can the desired chemical activation be achieved without thermal damage to the surface. Unstable or substoichiometric flames, on the other hand, can lead to insufficient activation or even damage to the material, for example, through local overheating.

The effectiveness of the treatment can be verified by measuring the surface energy. In addition to the common method of determining the contact angle, test inks with defined surface tensions are often used in industrial practice. These allow for a quick, qualitative to semi-quantitative assessment of treatment success directly in the production environment.

Overall, flame treatment is an established, robust and inline-capable process for surface activation, which is widely used, especially for thermally resistant and non-polar plastics.